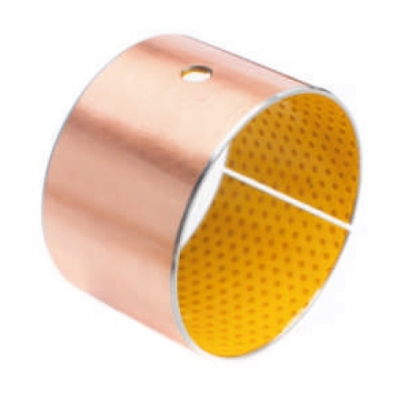

KDB 206

Material

Mild steel + porous sintered copper + PEEK/resin filler (black)

Application features

Low friction factor and wear rate, impact resistance and fatigue resistance

The sliding layer can be set with oil holes or oil tanks to achieve regular grease refueling

Grease lubrication is suitable for swinging and rotating movement at heavy loads and low speeds

Oil-film lubrication is suitable for rotational movement at high PV values

Higher temperature resistance and chemical stability

The thickness of the sliding layer is 0.2~0.4, which can be finished to improve the accuracy

The filler does not contain Pb, which meets environmental protection requirements

Used in hydraulic motors, high-pressure gear pumps, high-pressure water injection pumps, diesel common rail pumps, heavy-duty braking systems and baking equipment, etc.

| Characteristics | Unit | Border lubrication | Oil-film lubrication |

| Max. dynamic load | Mpa | 140 | 100 |

| Max. static load | Mpa | 100 | 140 |

| Operating temperature | ℃ | -150 ~ +250 | -150 ~ +250 |

| Max. line speed | m/s | 2.5 | 5 |

| Max. PV | m/s·Mpa | 2.8 | 120 |

| Friction factor | 0.08 0.12 | 0.02 0.08 |