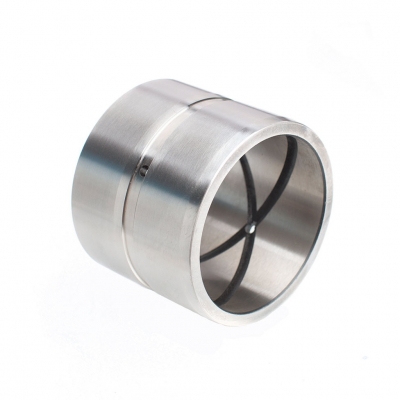

KDB 605

Craft

Carburizing and quenching + machining

Application features

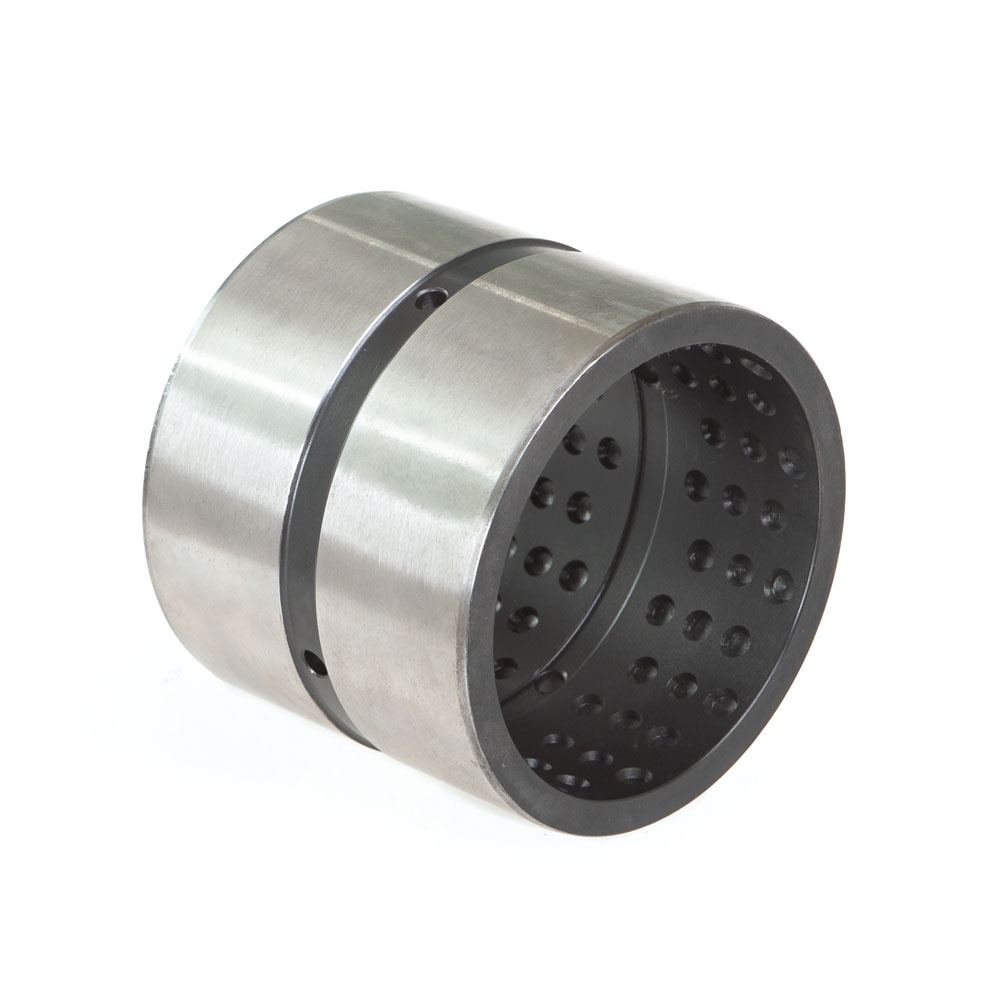

With 20CrMnTi, 20CrMo, 42CrMo and other steels as the matrix, the surface is spherical honeycomb oil holes and oil tanks, carburized and quenched after finishing, and then the surface is composite with wear-reducing materials to form a high-hardness surface layer with wear resistance, fatigue resistance, long life, and the middle layer has the advantages of high toughness and impact resistance.

Suitable for harsh working conditions such as high load, low speed, impact load, etc.

Used in excavators, rotary drilling rigs, large loaders, continuous wall grabbers, cranes, port machinery and other joint parts

| Characteristics | Unit | Grease lubrication |

| Max. dynamic load | Mpa | 250 |

| Operating temperature | ℃ | -100 ~ +350 |

| Max. line speed | m/s | 0.5 |

| Max. PV | m/s·Mpa | 2.5 |

| Surface hardness | HRC | 56 ~ 62 |

| Coefficient of linear expansion | 10-15/℃ | 1.1 |