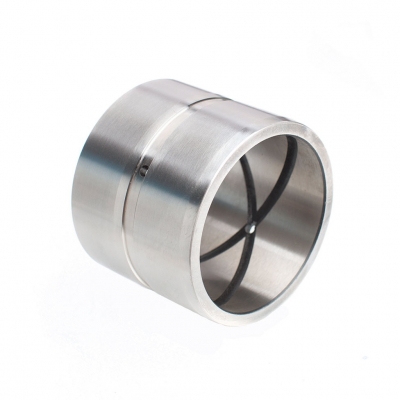

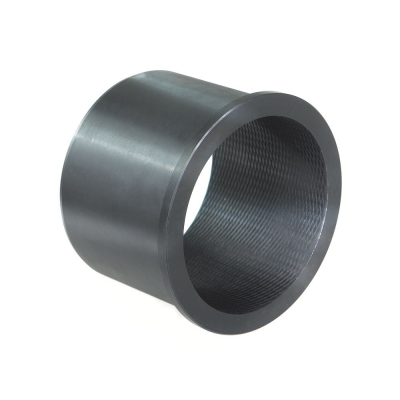

KDB 603

Craft

Normalizing or quenching and tempering + high frequency quenching + machining

Application features

Medium carbon steels such as 45# and 40Cr are used as the matrix for normalizing or tempering, with spiral grooves on the surface, double 8-shaped, cross or three-ring oil lines, high-frequency quenching and finishing, and then surface phosphating and vulcanization treatment to form a high-hardness surface layer with wear resistance, fatigue resistance, long life, high toughness and impact resistance in the middle layer, etc.

Suitable for harsh working conditions such as high load, low speed, impact load, etc.

Used in joint parts such as excavators, loaders, cranes, etc.

| Characteristics | Unit | Grease lubrication |

| Max. dynamic load | Mpa | 250 |

| Operating temperature | ℃ | -100 ~ +250 |

| Max. line speed | m/s | 0.15 |

| Max. PV | m/s·Mpa | 1.5 |

| Surface hardness | HRC | 52~60 |