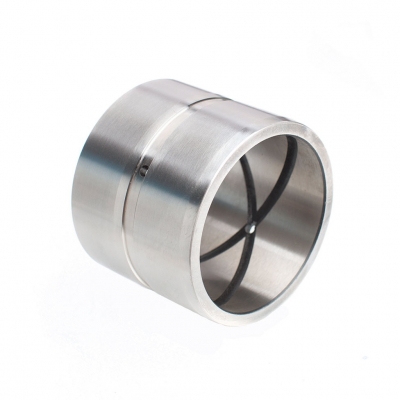

KDB 600

Craft

Stamping and rolling + carbon-nitrogen co-infiltration

Application features

With SPCC, ST12 and other thin-walled mild steels as the matrix, it is stamped or rolled into a shape, and then subjected to carbon-nitrogen co-infiltration heat treatment to form a high-hardness wear-resistant layer on the surface.It has the advantages of stable size, uniform hardness, high wear resistance, high toughness, impact resistance, long life, etc.

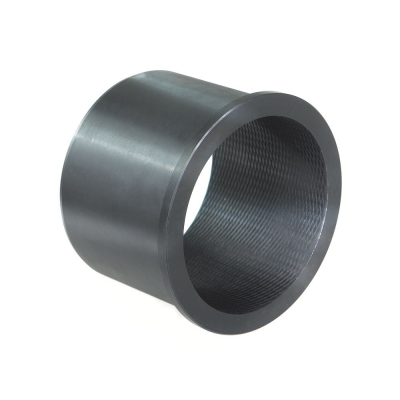

Suitable for medium and low load, medium and low speed, impact load conditions

Used in automobile rocker arms, leaf spring lugs, differential sun wheels and other parts

| Characteristics | Unit | Grease lubrication |

| Max. dynamic load | Mpa | 100 |

| Operating temperature | ℃ | -100 ~ +250 |

| Max. line speed | m/s | 0.10 |

| Max. PV | m/s·Mpa | 1.00 |

| Non-heat-treated hardness | HB | 90~140 |

| Carbon-nitrogen co-infiltration hardness | HV0.1 | 400~700 |